. Standardization of mining methods; a series of important articles reprinted from Engineering and mining journal. ch the ground requires, and withthe exact gage, cutting edge, and reaming surfaces.Four pieces of steel (the 1st, 2d, 3d and 4th) should befastened with an iron ring into one bundle, to facili-tate handling. This bundle contains all the steel re-quired for the drilling of one hole to its proper depth,and can be used over again until the steel becomes dulled. Another problem is to keep the steel moving. Forexample, after it passes through the drill-sharpeningshop, it is transported

Image details

Contributor:

The Reading Room / Alamy Stock PhotoImage ID:

2AFP9FEFile size:

7.2 MB (285.9 KB Compressed download)Releases:

Model - no | Property - noDo I need a release?Dimensions:

1466 x 1705 px | 24.8 x 28.9 cm | 9.8 x 11.4 inches | 150dpiMore information:

This image is a public domain image, which means either that copyright has expired in the image or the copyright holder has waived their copyright. Alamy charges you a fee for access to the high resolution copy of the image.

This image could have imperfections as it’s either historical or reportage.

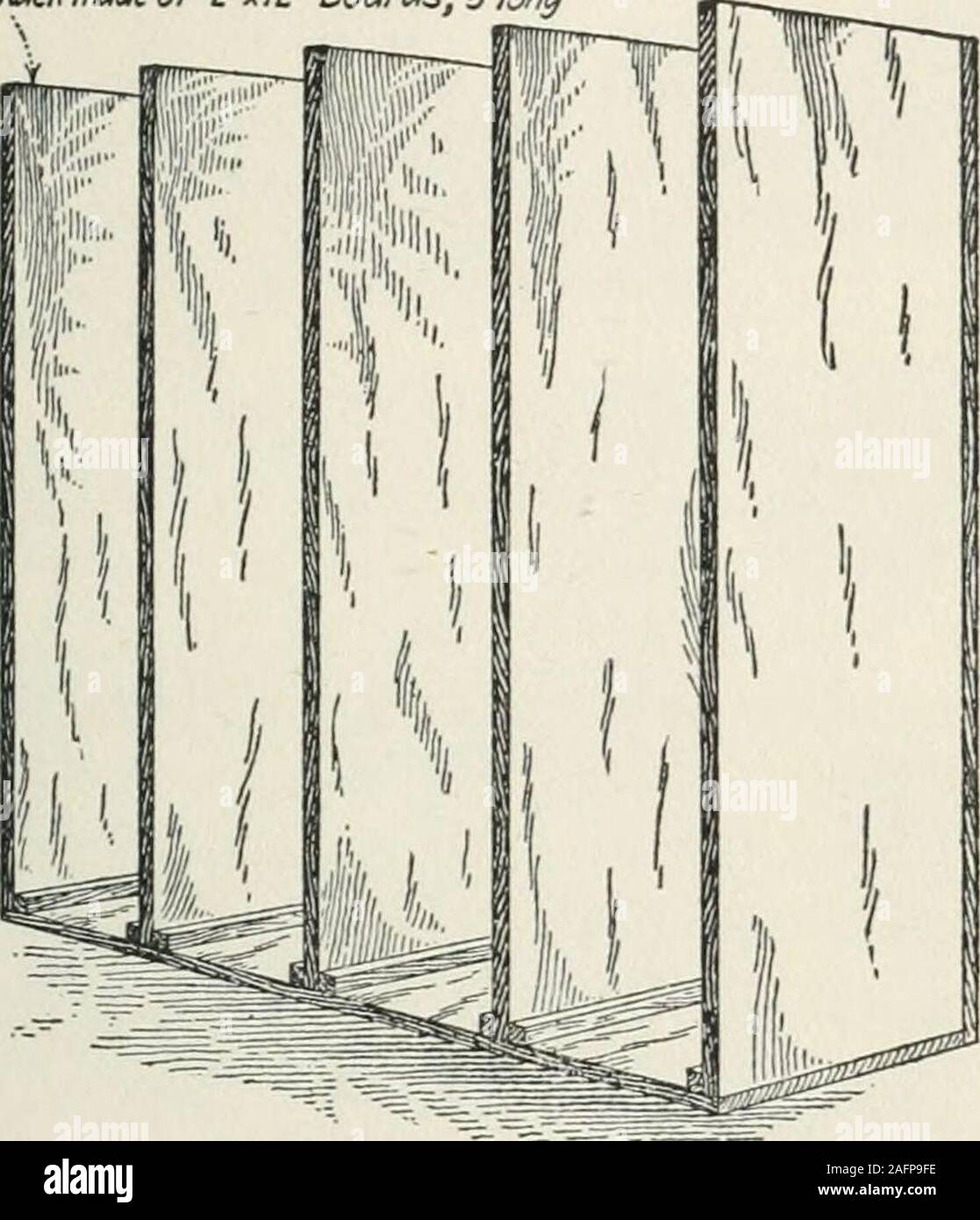

. Standardization of mining methods; a series of important articles reprinted from Engineering and mining journal. ch the ground requires, and withthe exact gage, cutting edge, and reaming surfaces.Four pieces of steel (the 1st, 2d, 3d and 4th) should befastened with an iron ring into one bundle, to facili-tate handling. This bundle contains all the steel re-quired for the drilling of one hole to its proper depth, and can be used over again until the steel becomes dulled. Another problem is to keep the steel moving. Forexample, after it passes through the drill-sharpeningshop, it is transported to the shaft, lowered in steelcars to the various stations, and taken thence to thesteel racks. Frequently, it is merely stood up on the STANDARD EQUIPMENT 87 ground, and becomes plugged before it is put in themachine. This may be avoided by the use of steel racks, where it is sorted into different lengths and kinds.These racks (see Fig. 1) should be on all levels under-ground, at convenient distances from working places.The steel is taken to the racks from the shaft stations on HKh made of ZxIZ Boards, S/on^. Fig. 1. Underground Steel Rack trucks, and distributed to the different tool cars by thetool nippers, who, in turn, take the dull steel back onsmall trucks to the shaft stations. Here it is put intothe steel cars in which the sharp steel has been broughtdown, and sent to the surface. A surplus of sharpsteel should always be kept in the central steel racks, sothat a man who has not enough steel to finish his roundcan obtain more. The central steel rack should be near the tool houseand also close to the powder magazine, so that thepowderman who gives out the powder, caps, and fusecan also attend to giving out the tools, supplies, andsteel. He should also check all that comes out, in order 88 STANDARDIZATION OF MINING METHODS that a record may be kept of the machines and otherequipment. Standard Equipment for Drifting Work To have a complete outfit, so that the machine manwi