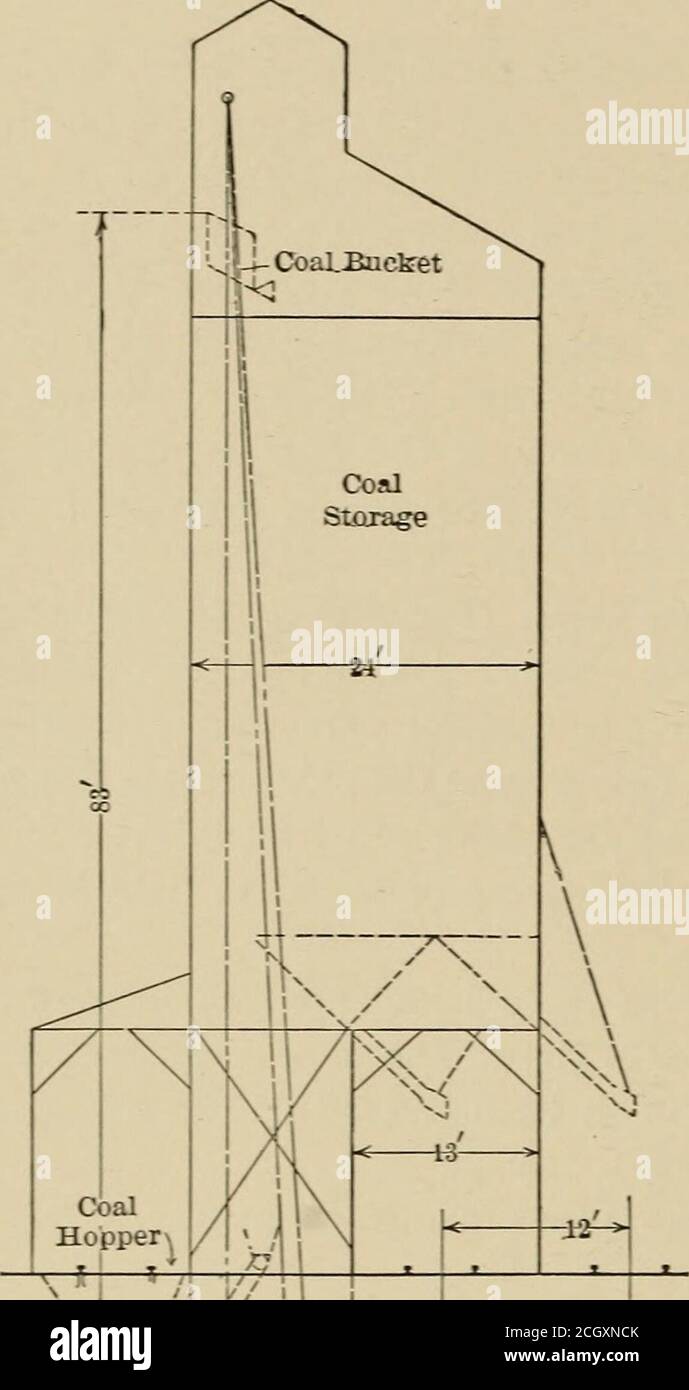

. Railroad structures and estimates . ipping arrangements, the buckets being designed to hold threetons and are self-clearing. They are operated by hoist with cable drive and 25 horsepowermotor controlled by the operator in the engine room. At a speedof 60 feet per minute 100 tons can be delivered to the elevatedpocket per hour. The approximate cost of the plant complete averages from$12,000 to $15,000. Belt Conveyor. (Fig. 70.) — This plant may consist of one ora series of pockets with an inclined belt on a 25-degree slope, fedfrom a track hopper beneath the coal car track, the coal beingdeli

Image details

Contributor:

Reading Room 2020 / Alamy Stock PhotoImage ID:

2CGXNCKFile size:

7.1 MB (142.3 KB Compressed download)Releases:

Model - no | Property - noDo I need a release?Dimensions:

1151 x 2170 px | 19.5 x 36.7 cm | 7.7 x 14.5 inches | 150dpiMore information:

This image is a public domain image, which means either that copyright has expired in the image or the copyright holder has waived their copyright. Alamy charges you a fee for access to the high resolution copy of the image.

This image could have imperfections as it’s either historical or reportage.

. Railroad structures and estimates . ipping arrangements, the buckets being designed to hold threetons and are self-clearing. They are operated by hoist with cable drive and 25 horsepowermotor controlled by the operator in the engine room. At a speedof 60 feet per minute 100 tons can be delivered to the elevatedpocket per hour. The approximate cost of the plant complete averages from$12, 000 to $15, 000. Belt Conveyor. (Fig. 70.) — This plant may consist of one ora series of pockets with an inclined belt on a 25-degree slope, fedfrom a track hopper beneath the coal car track, the coal beingdelivered to the belt by automatic feeders. A 30 inches wide belt, 180 feet run, with a speed of 100 feet perminute will deliver 50 tons per hour. The belt and its supports with a gang walk is usually housedin and supported by trestle, under which the engine room isplaced. The coal pockets are wood construction usually, and a sand shedbeneath the coal wharf can be arranged and the sand shot by air 150 RAILROAD STRUCTURES AND ESTIMATES.. i<¥ il Hoisting Drum f^l L A I I I I M- V _ / 1/