Engineering and Contracting . gress has beenmade in eliminating piping and segregation inthe steel ingot. By adopting an inverted ingotand pouring with a refractory top the pipingIsas been reduced to such an extent that thesale of electric steels on a competitive pricebasis with open-hearth steel seems not fardistant. The most inxportant improvementin manufacturing manganese steel rails con-sists of the installation of a quenching tank oflarge proportions. The toughness of man-ganese steel depends upon quenching froin thetemperature at which the rail is rolled, as con-trasted with the air cool

Image details

Contributor:

The Reading Room / Alamy Stock PhotoImage ID:

2AXCA1NFile size:

7.1 MB (245.9 KB Compressed download)Releases:

Model - no | Property - noDo I need a release?Dimensions:

2217 x 1127 px | 37.5 x 19.1 cm | 14.8 x 7.5 inches | 150dpiMore information:

This image is a public domain image, which means either that copyright has expired in the image or the copyright holder has waived their copyright. Alamy charges you a fee for access to the high resolution copy of the image.

This image could have imperfections as it’s either historical or reportage.

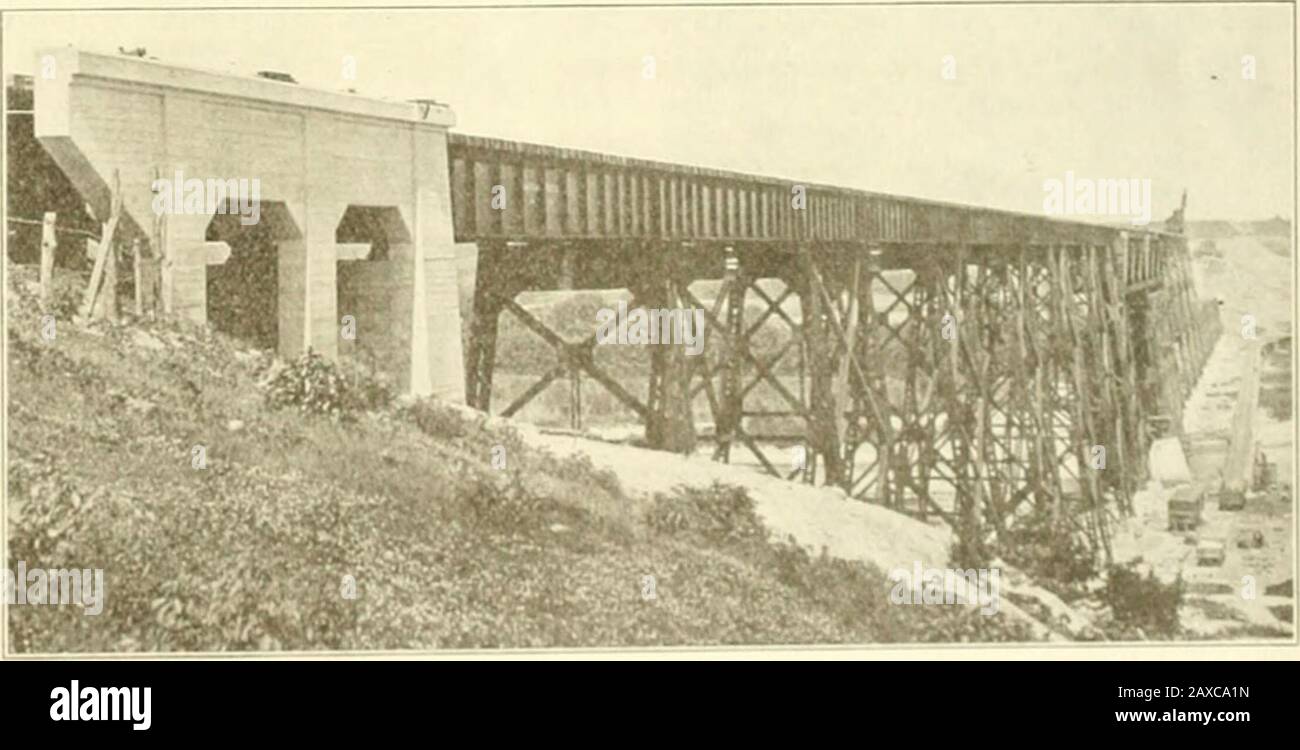

Engineering and Contracting . gress has beenmade in eliminating piping and segregation inthe steel ingot. By adopting an inverted ingotand pouring with a refractory top the pipingIsas been reduced to such an extent that thesale of electric steels on a competitive pricebasis with open-hearth steel seems not fardistant. The most inxportant improvementin manufacturing manganese steel rails con-sists of the installation of a quenching tank oflarge proportions. The toughness of man-ganese steel depends upon quenching froin thetemperature at which the rail is rolled, as con-trasted with the air cooling of steel rails onthe hot beds. To obtain the best results thebath must be of sufficient size and must havea circulation of sufficient activity to dissipatethe heat from the rails without any appreciablerise in its own temperature. The quenchingof the rails follows immediately after camber-ing, the rails being fed continuously into thetank. It has not yet been po.-sible to over-come the obstacles which manganese steel pre-. Fifl. 12. View of West Portion of Des Moines River Viaduct—Construction Track is Shown at Base of Viaduct. railway companys forces, with Mr 1.. 11.1 lowell in charge. Exhibit of United States Steel Corpora-tion at San Francisco.— The aiuiniinriin-niis made that the Inited .States Steel Ciition and its subsidiary companies prto have a comprehensive exhibit of its opera-tions at the Panama-Pacilic Exposition in SanFrancisco in the year 101.1. Il will begin withthe ordiclds and carry on an educative picture, )f its . in ore mining, rail ami water lrans|. k o|ierations, coil, roke .ind pig irci |ii Mi.ii.m, steel manufacturing in itsvarious lines and will also present in a ma-terially displayed way the processes of manu-facturing of many of its subsidiary companies scnts lo machining, and the drilling of holesfor bonding is still impossible. Punches havebeen designed and installed which give a sat-isfactory hole, but their operation is expensive, .lie to br