. Automotive industries . operator, and longer life of the car. The engine has six cylinders, 4V2 by 4% in., cast intwo blocks of three, and with a seven-bearing crank-shaft of 2% in. diameter. The crankshaft is forgedfrom nickel chrome steel and isfinished all over, and the bearingsare lapped after being ground, toobtain a smoother surface than ispossible to obtain by grinding.The crankshaft is, of course, heat-treated, and it is noteworthy thatthe heat treatment is applied onlyafter most of the surplus stockhas been removed, in order £o en-sure more rapid and uniform cool-ing on quenching. T

Image details

Contributor:

Reading Room 2020 / Alamy Stock PhotoImage ID:

2CHT6H5File size:

7.1 MB (238.1 KB Compressed download)Releases:

Model - no | Property - noDo I need a release?Dimensions:

2638 x 947 px | 22.3 x 8 cm | 8.8 x 3.2 inches | 300dpiMore information:

This image is a public domain image, which means either that copyright has expired in the image or the copyright holder has waived their copyright. Alamy charges you a fee for access to the high resolution copy of the image.

This image could have imperfections as it’s either historical or reportage.

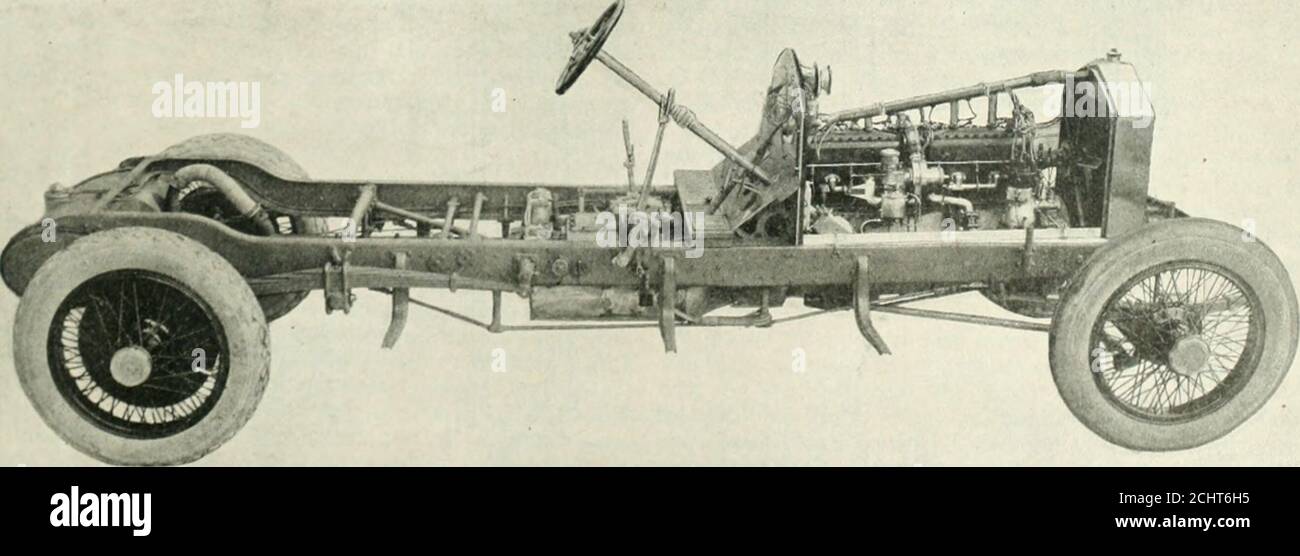

. Automotive industries . operator, and longer life of the car. The engine has six cylinders, 4V2 by 4% in., cast intwo blocks of three, and with a seven-bearing crank-shaft of 2% in. diameter. The crankshaft is forgedfrom nickel chrome steel and isfinished all over, and the bearingsare lapped after being ground, toobtain a smoother surface than ispossible to obtain by grinding.The crankshaft is, of course, heat-treated, and it is noteworthy thatthe heat treatment is applied onlyafter most of the surplus stockhas been removed, in order £o en-sure more rapid and uniform cool-ing on quenching. The bearing caps in the crank-case are made of nickel steel, heat-treated, and are held in place bymeans of bolts, rather than studsscrewed into the aluminum. Forboring out the main bearings inthe crankcase, dummy aluminum caps are made use of.The steel caps are ground. The bronze-back, babbit-lined bushings are ground on the outside and are fittedinto the crankcase and the bearing cap with bluing to Front engine bracket. The Rolls-Royce chassis 596 AUTOMOTIVE INDUSTRIESTHE AUTOMOBILE March 17, 1921 insure a perfect seat, so that the joint will stand an oilpressure of 20 lb. per sq. in. Solid bronze liners areplaced between the two halves of the bearing, whitemetalled on the side toward the shaft. Adjustment forwear of the bearings is made by filing down the liners The engine is supported on the frame by a flexiblefour-point support on which the Rolls-Royce firm holdsa patent. The forward end of the crankcase rests ontwo bell cranks, one arm of each of which is connectedto a frame bracket and the other two arms of which areconnected by a tie rod (see sketch). The fulcrum ofthe bell cranks is on the crankcase. This constructionprotects the crankcase against stresses due to frame dis-tortion. Aluminum alloy pistons are used. Trouble from slapand seizing is prevented by slitting the skirt longitudi-nally on the pressure sides at a slight angle, and cir-cumferentially at the bottom