Annual report of the State Mineralogist for the year ending ... . ms to become too high,the doors are opened until the ore has cooled off sufficiently. When thedesired quantity of oxides has been formed, which will be after aboutsix hours, the heat is increased to cause the agglomeration of the ore,which is drawn out on the floor and allowed to solidify, when it is readyfor the smelting operation. THE WATER JACKET BLAST FURNACE. The blast furnace employed is considerably higher than the Castil-iau furnace (Figs. 21 and 22) described above, and differs from it in manyways. The furnace is a typi

Image details

Contributor:

The Reading Room / Alamy Stock PhotoImage ID:

2AWT4GHFile size:

7.1 MB (275.4 KB Compressed download)Releases:

Model - no | Property - noDo I need a release?Dimensions:

1370 x 1823 px | 23.2 x 30.9 cm | 9.1 x 12.2 inches | 150dpiMore information:

This image is a public domain image, which means either that copyright has expired in the image or the copyright holder has waived their copyright. Alamy charges you a fee for access to the high resolution copy of the image.

This image could have imperfections as it’s either historical or reportage.

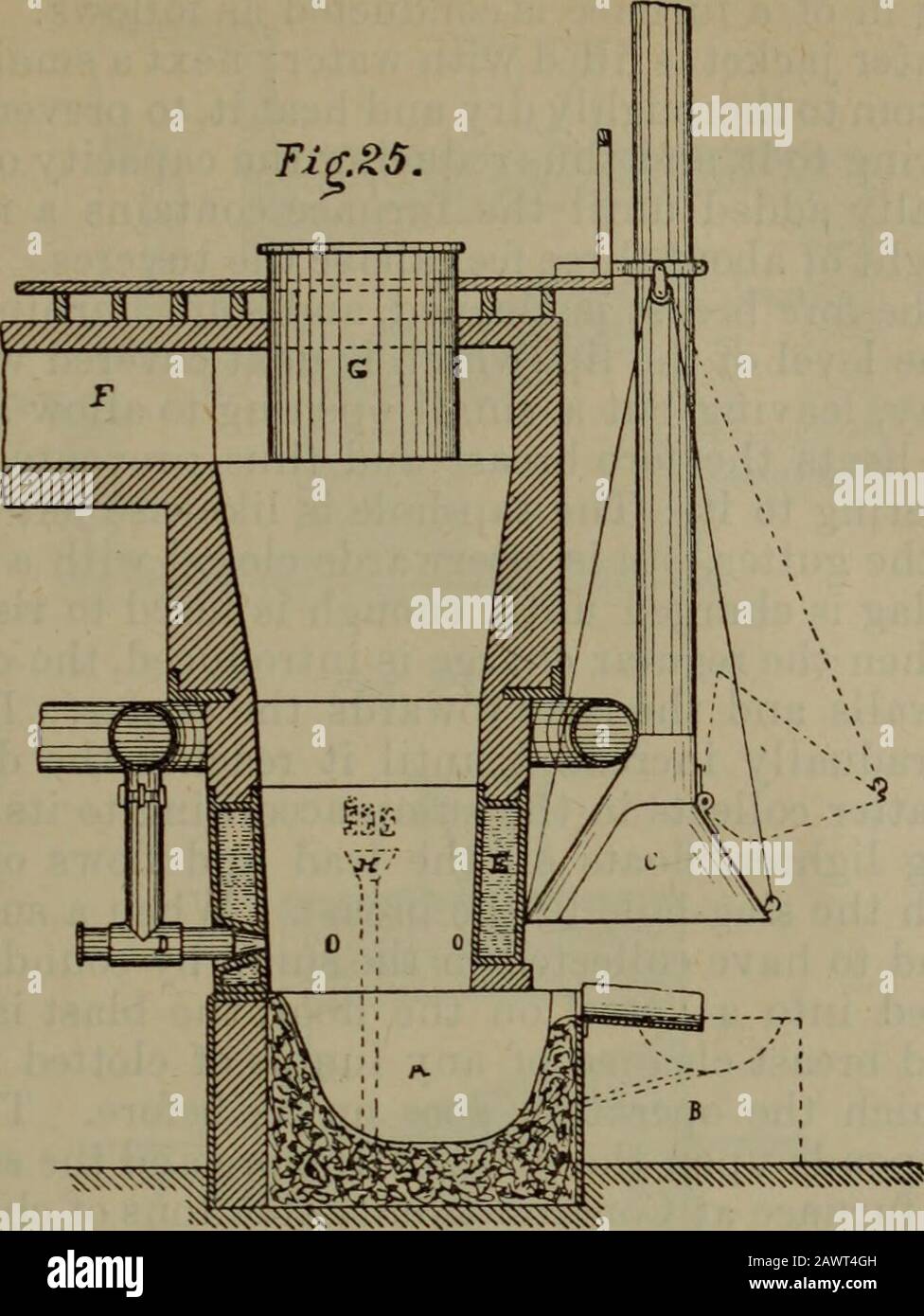

Annual report of the State Mineralogist for the year ending ... . ms to become too high, the doors are opened until the ore has cooled off sufficiently. When thedesired quantity of oxides has been formed, which will be after aboutsix hours, the heat is increased to cause the agglomeration of the ore, which is drawn out on the floor and allowed to solidify, when it is readyfor the smelting operation. THE WATER JACKET BLAST FURNACE. The blast furnace employed is considerably higher than the Castil-iau furnace (Figs. 21 and 22) described above, and differs from it in manyways. The furnace is a typical modern blast furnace, such as is used, with slight modifications, in every well appointed smelting establish-ment. To prevent the loss of time, labor, and temperature occasioned by thefrequent burning through of the lower portion of the furnace, the brick-work in that part has been replaced by a so called water jacket, anannular cylinder of iron about three feet high, which is kept cool by aconstant stream of cold water running through it. LEAD SMELTING. 825. The water jacket E is either cast in one piece or constructed of one-half-inch boiler plate. The position and number of the tuyeres is a matter of importance. The usual number is five, which pierce at equal distances the lowerthird of the water jacket and converge towards the center of the furnace.By reducing the number of tuyeres, or placing them farther from thebreast, the water would cool the interior of the jacket to such a degreeas to interfere with the regular descent of the charge. The water entersthrough an inlet pipe at the bottom of the jacket, supplied with a valveto regulate the supply, and leaves on the opposite side near the upperedge of the jacket. The arrangement shown in dotted lines in Fig.25 can be recommended, as the workman may readily estimate thequantity and temperature of the water as it falls from the outlet pipesi i i into the funnel H communicating with the drain, and regulatethe cold water su